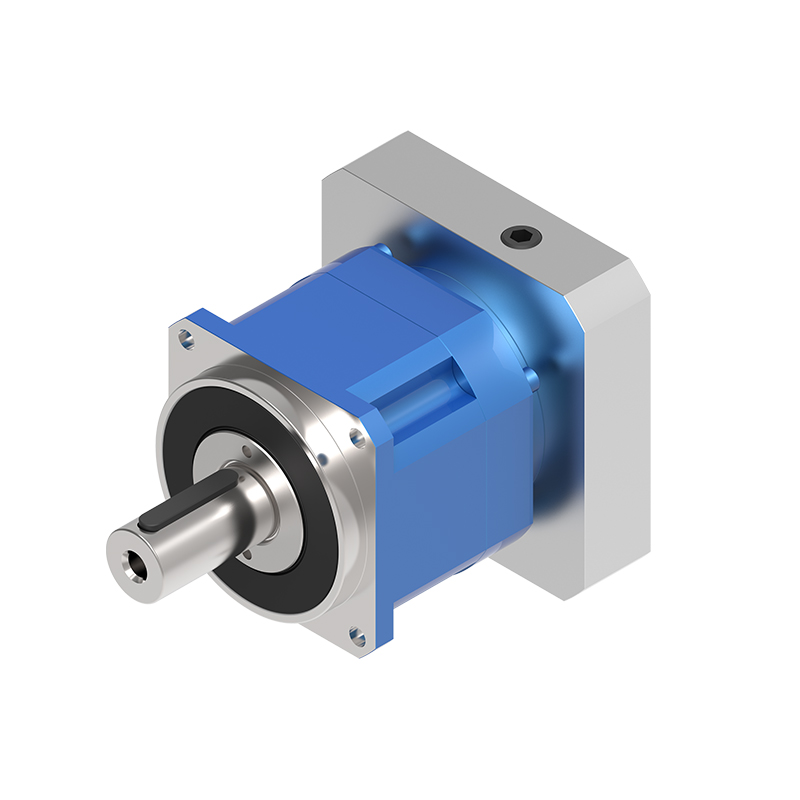

Low Backlash High Precision Torque AHB Planetary Gearbox Reducer

Cat:Planetary Reducer

Features of planetary reducer 1. Quiet: Use helical gears to achieve smooth and quiet operation;2. H...

See DetailsIn the world of precision motion control, the integration of a stepper motor planetary gearbox represents a pinnacle of engineering, combining the precise positioning of a stepper motor with the robust power transmission of a planetary gearhead. This synergy is crucial for applications demanding high torque, compact size, and exceptional accuracy. Our company, leveraging cutting-edge Japanese electromechanical R&D technology and meticulous production processes, is dedicated to the research and development of these critical components. Situated in the National Economic and Technological Development Zone of Pinghu City, Zhejiang Province—a core area of China's premier electromechanical industrial parks—we are at the forefront of product structure optimization and upgrading, serving the dynamic Yangtze River Delta region and beyond.

A stepper motor planetary gearbox is a mechanical assembly that reduces the output speed of a stepper motor while increasing its output torque. The "planetary" name comes from the gear system's configuration, where multiple "planet" gears revolve around a central "sun" gear, all contained within an outer "ring" gear. This compact and efficient design is renowned for its high torque density, excellent stiffness, and reliable performance.

Applications requiring significant force in a compact package are the primary domain of a high torque stepper motor planetary gearbox. The planetary design inherently distributes load across multiple planet gears, leading to a much higher torque capacity compared to other gearbox types of similar size.

In the realm of industrial automation, reliability and precision are non-negotiable. A planetary gearbox for stepper motor automation enhances the stepper motor's capabilities, making it suitable for continuous, high-cycle operations.

Backlash—the slight movement between mating gears when direction is reversed—can be detrimental to precision. A low backlash stepper motor gearbox is engineered to minimize this play, which is critical for applications like CNC machining, 3D printing, and optical positioning systems.

The following table illustrates the typical backlash ranges for different gearbox technologies, highlighting the advantage of precision planetary systems.

| Gearbox Type | Typical Backlash Range | Suitability for High-Precision Tasks |

| Spur Gearbox | 1° to 5° | Low |

| Worm Gearbox | 10 arc-min to over 1° | Medium |

| Planetary Gearbox (Standard) | 5 to 15 arc-min | High |

| Precision Planetary Gearbox (Low Backlash) | < 3 arc-min | Very High |

Off-the-shelf solutions are not always sufficient. The demand for a custom stepper motor with planetary gearhead arises when standard products cannot meet specific application requirements for size, performance, or interface.

Choosing the correct gear ratio is fundamental to system performance. The process of stepper motor planetary gearbox ratio selection involves balancing the need for speed reduction and torque multiplication with the motor's inherent capabilities.

The table below summarizes the trade-offs involved when selecting a gear ratio for a stepper motor planetary gearbox.

| Selection of a Lower Ratio | Selection of a Higher Ratio |

| Results in a higher output speed. | Results in a lower output speed. |

| Provides less torque multiplication. | Provides greater torque multiplication. |

| Generally offers higher efficiency. | May have slightly lower efficiency. |

| Better for applications prioritizing speed over brute force. | Ideal for applications requiring high torque at low speeds. |

Planetary gearboxes are preferred due to their high torque-to-size ratio, excellent torsional stiffness, low backlash (in precision models), and coaxial input/output shaft alignment, which simplifies system design and integration compared to offset-shaft gearboxes like worm or spur gears.

Our adherence to Japanese meticulous production processes and cutting-edge R&D technology ensures that every stepper motor planetary gearbox is manufactured with extreme attention to detail. This philosophy results in superior gear meshing, tighter tolerances, enhanced durability, and consistent, reliable performance that meets the highest international standards.

The main advantage of a low backlash stepper motor gearbox is its significant improvement in positional accuracy and repeatability. By minimizing the dead zone during direction reversal, it eliminates positioning errors, reduces settling time, and is essential for applications like CNC machining and robotic surgery.

Absolutely. We specialize in developing custom stepper motor with planetary gearhead solutions. Our engineering team can work with you to determine and manufacture the ideal gear ratio, along with other custom parameters, to perfectly match your application's torque, speed, and physical requirements.

The three most critical factors are:

Proper selection and maintenance are key to maximizing service life.