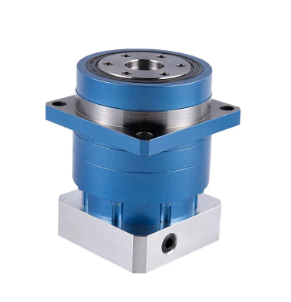

Output Variable High Precision Torque Planetary Reducer ALR Series

Cat:Planetary Reducer

Features of planetary reducer1. Quiet: Use helical gears to achieve smooth and quiet operation;2. Hi...

See DetailsIn the world of precision motion control and power transmission, the planetary gearbox stands as a cornerstone technology. Its unique configuration offers unparalleled advantages in a compact form factor. Among these, the High Torque Planetary Gearbox is particularly revered for its ability to deliver exceptional rotational force while maintaining efficiency and reliability. This article delves deep into the engineering, applications, and selection criteria of these powerful components, providing a detailed resource for engineers and industry professionals. Drawing on leading global R&D traditions, such as the meticulous Japanese approach to electromechanical design and production processes, modern manufacturers continue to push the boundaries of performance and durability in gearbox technology.

A High Torque Planetary Gearbox is a specialized type of gear system where the input and output shafts are aligned. Its name derives from its sun-and-planet-like structure, which consists of three main components:

This arrangement allows for torque multiplication and speed reduction in a highly symmetric and balanced package. The "high torque" designation refers to models engineered specifically to handle and transmit significantly higher levels of rotational force compared to standard planetary units, making them ideal for demanding industrial applications [1].

The superior performance of these gearboxes stems from their fundamental design.

The torque multiplication is directly related to the gear ratio. When a motor provides input to the sun gear, the planet gears, held by a carrier, rotate and walk along the stationary ring gear. This action causes the carrier to rotate at a reduced speed but with dramatically increased output torque. The more planet gears engaged, the greater the load distribution and potential torque capacity.

High Torque Planetary Gearboxes are the workhorses of heavy-duty automation. Their robustness is critical in sectors where failure is not an option.

Choosing the correct gearbox is crucial for system longevity and performance. Here are the critical parameters to evaluate.

Determine the peak and continuous torque demands of your application. Always select a gearbox with a rated torque exceeding your maximum requirement, applying an appropriate service factor (often 1.5 or higher) for shock loads or uneven operations.

The ratio defines the speed reduction and torque multiplication. Higher ratios yield higher torque. Backlash, the slight movement between meshed gears, should be minimized for precision applications like robotics or CNC machinery.

Consider flange mounting, foot mounting, or shaft-mounted designs. Lubrication is vital for heat dissipation and wear protection; options include grease or oil bath, with some units being maintenance-free.

To provide actionable insights, we address several common, specific queries related to High Torque Planetary Gearbox performance and selection.

A common challenge is balancing the need for immense force with the need for exact positioning. High Torque Planetary Gearbox for robotics applications is a prime example where this balance is essential.

While traditional high-torque designs might prioritize robustness over precision, advancements in manufacturing have made high-torque, low-backlash planetary gearboxes a reality. These units integrate precision-ground gears, pre-loaded bearings, and specialized assembly techniques to minimize angular backlash while maintaining high torque capacity. This makes them ideal for robotic welding arms or heavy-duty assembly robots where both power and pinpoint accuracy are non-negotiable.

For equipment operating in challenging environments, standard gearboxes may fail prematurely. This is where a heavy duty planetary gearbox for construction equipment comes into play.

These gearboxes are engineered with specific enhancements:

In sectors like mining or energy, unexpected downtime leads to massive losses. Selecting a low backlash high torque planetary gearbox designed for reliability involves looking beyond basic specs.

Key features that signal high reliability include integrated condition monitoring ports for vibration or oil analysis, designed-in redundancy (such as extra bearing support), and the use of carburized and hardened gear steels for superior pitting and wear resistance. The design philosophy, akin to the meticulous Japanese production process, which emphasizes precision tolerances and rigorous testing at every assembly stage, is a hallmark of highly reliable gearboxes [2].

Efficiency directly impacts operating costs and thermal management. For applications like winches or large conveyor drives, an efficiency high torque planetary gear drive is paramount.

Planetary gears are inherently efficient (often 95-98% per stage), but several factors influence the final number:

| Factor | Impact on Efficiency | Design Consideration |

|---|---|---|

| Gear Tooth Design | Precision-ground teeth with optimized profiles reduce sliding friction. | Higher manufacturing cost, but significantly lower energy loss. |

| Bearing Friction | High-quality, low-friction bearings (e.g., tapered roller) minimize losses. | Critical in high-radial-load applications. |

| Lubrication | Proper viscosity and churning losses must be balanced. | Synthetic oils can reduce churning losses at high speeds. |

| Sealing | Contact seals (e.g., lip seals) create more drag than non-contact labyrinth seals. | Seal selection is a trade-off between protection and efficiency. |

While initial cost is a factor, the total cost of ownership (TCO) is more telling. For continuous operation in a plastic injection molding machine, a high torque planetary gearbox for plastic injection molding machine represents a critical investment.

A comparison between a standard unit and a premium, durability-optimized unit reveals the long-term benefits:

| Cost Component | Standard Gearbox | Premium High-Torque Gearbox |

|---|---|---|

| Initial Purchase Price | Lower | Higher |

| Energy Consumption | Higher due to lower efficiency | Lower due to optimized design |

| Maintenance Frequency | More frequent lubrication, seal changes | Extended maintenance intervals |

| Downtime & Production Loss | Higher risk of unexpected failure | Lower risk, higher predictability |

| Lifespan | Shorter | Significantly longer |

Therefore, the premium gearbox, often developed using leading design and development technology for product optimization, typically offers a far lower TCO despite its higher sticker price.

The evolution of the High Torque Planetary Gearbox is driven by relentless innovation in materials science, simulation software, and manufacturing techniques. Modern computational tools allow for the topological optimization of gearbox housings, making them lighter yet stronger. The integration of sensor technology for predictive maintenance is becoming a standard in advanced models. Furthermore, the geographical context of manufacturing plays a role. For instance, production within specialized industrial clusters, such as those found in the National (Jiaxing) Electromechanical Components Industrial Park, fosters a ecosystem of supply chain excellence and technical specialization. Being located in a dynamic economic region like the Yangtze River Delta ensures access to advanced logistics and a skilled workforce, contributing to consistent quality and technological advancement in electromechanical components [3].

The High Torque Planetary Gearbox is a masterclass in mechanical efficiency and power density. From enabling the precise movements of a high torque planetary gearbox for robotics to withstanding the brutal forces encountered by a heavy duty planetary gearbox for construction equipment, its versatility is unmatched. When selecting a unit, focusing on specific needs—whether it’s the precision of a low backlash high torque planetary gearbox, the operational economy of an efficiency high torque planetary gear drive, or the rugged reliability needed for a high torque planetary gearbox for plastic injection molding machine—is key to optimal system performance. By prioritizing engineering quality, advanced materials, and a holistic view of total cost of ownership, businesses can leverage this technology to build more robust, efficient, and reliable machinery.

The primary difference lies in their designed torque capacity and construction. A High Torque Planetary Gearbox is built with larger, stronger gear teeth, wider bearings, and a more robust housing to handle substantially higher radial and axial loads. It often uses higher-grade materials and more precise heat treatment to prevent deformation under extreme stress.

You need to determine the output shaft’s required torque (T_out). This involves calculating the load torque (from the machine's mechanics) and multiplying it by a service factor (SF) for safety: T_required = T_load × SF. The gearbox's rated output torque must exceed T_required. Consult the gearbox manufacturer's catalog and application engineering guidelines for detailed calculations, which consider inertia, cycle time, and shock loads.

Backlash is the free movement between meshing gears. In precision applications like robotics or CNC machining, excessive backlash causes positional inaccuracy and vibration. In a low backlash high torque planetary gearbox, it is minimized through precision machining of gear teeth, selective assembly of gear sets, the use of pre-loaded bearings, and sometimes specialized tooth profile modifications.

Yes, planetary gearboxes are reversible. By driving the carrier (usually the output in a speed reducer) and taking output from the sun gear, you can achieve a speed increase. However, the torque output will be correspondingly lower. It's crucial to verify with the manufacturer, as some designs may have lubrication or bearing limitations in this mode.

Key warning signs include:

Regular preventive maintenance, as per the manufacturer's schedule, is the best way to avoid catastrophic failure.

[1] Dudley, D. W. (1994). *Handbook of Practical Gear Design*. CRC Press. (Reference for fundamental planetary gear operation and torque principles).

[2] Japanese Standards Association. (2015). *JIS B 1702-1:2015 - Cylindrical gears — ISO system of flank tolerance classification — Part 1: Definitions and allowable values of deviations relevant to flanks of gear teeth*. (Reference for precision manufacturing and tolerance standards associated with meticulous production processes).

[3] Chen, X., & Sun, Y. (2021). *Industrial Cluster Development and Technological Innovation in China's Yangtze River Delta Region*. Journal of Economic Geography, 21(3), 455-478. (Reference for the impact of specialized industrial parks on electromechanical component manufacturing).