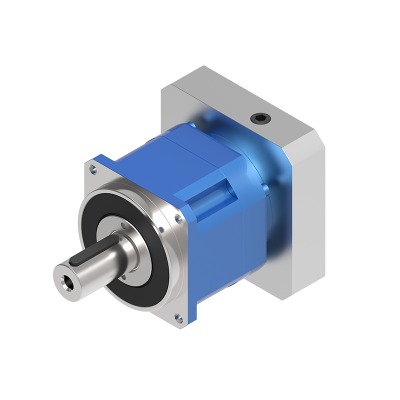

Helical Tooth Transmission Gearbox Planetary Reducer AHL Series for Servo Motor

Cat:Planetary Reducer

Planetary reducers have been widely used in many industries for their performance. Their uniquely de...

See DetailsA harmonic reducer is a type of gear system commonly used in precision applications, offering exceptional torque output and compact size. These devices operate based on the principle of elastic deformation, which allows them to achieve high reduction ratios without compromising on performance. They are widely used in fields like robotics, industrial automation, and other sectors requiring high precision and efficiency.

The working principle of a harmonic reducer revolves around the deformation of a flexible spline that transmits motion. A motor-driven wave generator distorts the spline, creating a harmonic wave that meshes with the internal gear teeth, resulting in motion transmission. This design eliminates the need for traditional gear teeth and allows for a smooth and efficient reduction in speed.

When choosing a harmonic reducer, one of the primary considerations is its load capacity. The type of application dictates how much weight the reducer will need to support. For instance, robotics applications often require light, high-precision reducers, while heavy-duty industrial automation systems demand stronger, more durable reducers that can handle larger loads.

Precision is critical in many applications like robotics, where the harmonic reducer plays a vital role in delivering accurate motion. When selecting a harmonic reducer, efficiency also matters—reducers with high efficiency help minimize energy loss and maximize performance, ensuring your machinery operates at optimal levels.

Durability and ease of maintenance are essential when selecting a harmonic reducer. Depending on the application, the reducer should be able to withstand wear and tear while offering easy access for repairs or part replacements. Long-lasting reducers typically require less frequent maintenance and are more cost-effective over time.

While harmonic reducers and planetary gearboxes both serve similar functions, they differ significantly in design and performance. Planetary gearboxes rely on multiple gears that work in tandem, providing higher torque output but with more components that can wear out over time. Harmonic reducers, on the other hand, provide a compact, highly efficient solution, often with less backlash and reduced vibration.

| Feature | Harmonic Reducer | Planetary Gearbox |

| Efficiency | High | Moderate |

| Backlash | Minimal | Higher |

| Size | Compact | Bulkier |

The use of harmonic reducers in robotics and industrial automation provides significant benefits over traditional gear systems. Their compact size, high reduction ratios, and low backlash make them ideal for high-precision tasks. These reducers enable robotic arms to perform intricate movements with minimal error, enhancing overall system accuracy.

In robotics, where precision and efficiency are paramount, harmonic reducers are indispensable. These reducers allow for smooth and precise movements in robotic arms and other automated systems, ensuring that they can perform tasks with the utmost accuracy and minimal downtime.

For industrial automation applications, harmonic reducers offer exceptional durability and load-bearing capacity. These features make them ideal for assembly lines, material handling systems, and other high-demand processes that require reliable performance over long periods.

In heavy-duty applications such as mining or automotive manufacturing, harmonic reducers are selected for their robust build and high load tolerance. Their ability to handle extreme stress while maintaining precision makes them a go-to solution for industries that demand continuous, high-efficiency operation.

The lifespan of a harmonic reducer depends on the specific model, the materials used, and how well it is maintained. Generally, these reducers are designed to last for many years with minimal wear, but factors such as load capacity, environmental conditions, and frequency of use can affect their longevity.

Yes, harmonic reducers can be used in outdoor environments, but it’s important to choose models that are rated for outdoor use. These reducers often come with protective coatings to prevent corrosion from environmental factors such as moisture and dust.

Backlash in a harmonic reducer can be minimized by selecting a high-precision model designed for low backlash. Additionally, maintaining the reducer properly and ensuring it is correctly aligned in the system can further reduce backlash over time.