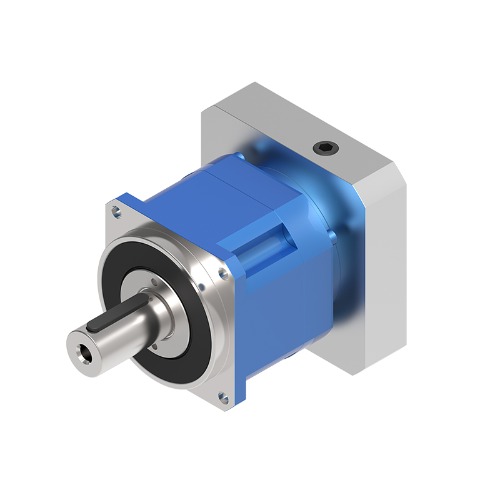

Low Backlash High Precision Torque AHB Planetary Gearbox Reducer

Cat:Planetary Reducer

Features of planetary reducer 1. Quiet: Use helical gears to achieve smooth and quiet operation;2. H...

See DetailsAt the heart of many precision motion control systems lies a powerful combination: the stepper motor and the planetary gearbox. A stepper motor is a brushless DC electric motor that divides a full rotation into a number of equal steps. It offers excellent positional control and torque at low speeds. However, a common limitation is the reduction of torque as the motor's speed increases. This is where the planetary gearbox, also known as an epicyclic gearbox, becomes an indispensable partner. By integrating a planetary gearbox with a stepper motor, engineers can significantly increase the output torque while reducing the output speed, thereby optimizing the motor's performance for applications requiring high torque at low to moderate speeds. The compact and robust nature of planetary gearboxes, characterized by their coaxial input and output shafts and high power density, makes them an ideal match for the precise control offered by stepper motors.

The synergy between these two components creates a solution that is greater than the sum of its parts. The primary reasons for this integration are multifaceted. Firstly, it results in a substantial increase in output torque. The gearbox multiplies the motor's torque by a factor approximately equal to the gear ratio, minus the efficiency losses. This allows a smaller, more cost-effective stepper motor to be used to achieve the same high-torque output that would otherwise require a much larger and more expensive motor. Secondly, it improves the system's resolution. While the stepper motor itself has a fixed step angle (e.g., 1.8° per step), the gearbox reduces this angle by the gear ratio. For instance, a 10:1 gearbox would make the output shaft move only 0.18° per motor step, enabling finer and more precise positioning. Furthermore, the gearbox helps in reducing the load inertia reflected back to the motor. This inertia matching is crucial for preventing step loss and ensuring stable, responsive control, especially during rapid acceleration and deceleration cycles.

A planetary gearbox consists of several critical components working in unison. The central component is the sun gear, which is directly driven by the input shaft connected to the stepper motor. Surrounding the sun gear are multiple planet gears, typically three or four, which are mounted on a carrier. These planet gears mesh simultaneously with both the sun gear and an outer ring with internal teeth, known as the ring gear or annulus gear. As the sun gear rotates, it drives the planet gears, which roll along the inside of the stationary ring gear. The rotation of the planet gears drives the planet carrier, which is connected to the output shaft. This arrangement allows for the torque to be distributed evenly across multiple planet gears, resulting in high torque capacity, compact size, and exceptional torsional stiffness with minimal backlash.

Choosing the appropriate planetary gearbox is a critical step in designing an efficient and reliable motion system. An incorrect selection can lead to premature failure, reduced performance, or inaccurate positioning. The process involves a careful evaluation of several key parameters that must align with both the stepper motor's characteristics and the application's demands. It is not merely about picking a gear ratio; it is about understanding the interplay between torque, speed, inertia, and physical constraints. This section will delve into the essential factors to consider, providing a structured approach to navigating the selection process and ensuring optimal compatibility between your stepper motor and the planetary gearhead.

Several technical specifications must be meticulously analyzed to make an informed decision. These parameters dictate the gearbox's performance and its suitability for the intended task.

The gear ratio is the fundamental parameter, defining the relationship between the input speed (motor side) and the output speed (load side). A higher ratio provides greater torque multiplication and greater speed reduction. Selecting the ratio requires a balance: a ratio that is too high may make it difficult to achieve the desired output speed, while a ratio that is too low may not provide sufficient torque. The required ratio can be calculated based on the desired output speed and the motor's available speed, or based on the torque required by the load and the torque provided by the motor.

The gearbox must be rated to handle the continuous and peak torque demands of the application. Exceeding the rated torque can cause catastrophic gear failure. Additionally, the overhung load and thrust load capacities are crucial. These specify the maximum permissible radial and axial forces that can be applied to the output shaft. Applications using pulleys, pinions, or belts can generate significant radial loads that must be supported by the gearbox's output bearings without causing excessive wear or failure.

Backlash is the angular clearance between mating gears, measured at the output shaft when the input is fixed. Low backlash is vital for applications requiring high positioning accuracy, such as in robotics or CNC systems. Gear efficiency indicates the percentage of input power successfully transmitted to the output; planetary gearboxes are known for their high efficiency, often ranging from 95% to 98% per stage. Finally, the expected service life, often rated in hours of operation, must be considered based on the application's duty cycle and operating environment.

Accurately calculating the torque requirement is the most critical step in ensuring system viability. The process involves determining the torque needed to accelerate the load inertia and to overcome any constant opposing forces. The total torque required at the gearbox output shaft is the sum of the acceleration torque (Ta) and the constant torque (Tc). The acceleration torque is derived from the inertia and the required acceleration rate (Ta = J * α), where J is the total system inertia at the output shaft and α is the angular acceleration. The constant torque includes forces like friction, gravity (in vertical axes), and process forces (e.g., pressing). Once the output torque (Tout) is known, the required motor torque (Tmotor) can be calculated using the gear ratio (R) and efficiency (η): Tmotor = Tout / (R * η). It is imperative to include a safety factor, typically between 1.5 and 2, to account for unforeseen variations and ensure reliable operation. How to calculate torque requirements for stepper motor gearbox systems is a fundamental skill for any engineer, preventing the common pitfalls of under-sizing or over-sizing the system.

The decision to incorporate a planetary gearhead yields a multitude of advantages that directly enhance the performance and capabilities of a motion control system. This integration transforms the inherent characteristics of a stepper motor, addressing its weaknesses and amplifying its strengths. The benefits extend beyond simple torque multiplication, impacting the system's dynamics, physical footprint, and long-term reliability. Understanding these benefits provides a clear rationale for why this combination is so prevalent in industries ranging from factory automation and medical technology to aerospace and consumer electronics.

The most immediate and obvious benefit is the dramatic increase in available output torque. Planetary gearboxes are renowned for their ability to transmit high torque in a compact volume. This high power density is achieved by distributing the transmitted load across multiple planet gears. This means that for a given outer diameter, a planetary gearbox can handle significantly more torque than other gearbox types, such as parallel shaft or worm gearboxes. This allows designers to select a smaller, more economical stepper motor to achieve the same torque output, leading to savings in cost, weight, and space. The compact, coaxial design also simplifies mechanical integration into existing assemblies.

While stepper motors are inherently accurate, their resolution is limited by their native step angle. A planetary gearbox effectively increases the system's resolution by the gear ratio. For example, a 1.8° stepper motor (200 steps/revolution) coupled with a 10:1 gearbox results in an output movement of 0.18° per step, effectively creating 2000 steps per revolution at the output shaft. This finer resolution allows for more precise positioning, which is critical in applications like optical positioning systems, precision dispensing, and micro-machining. Furthermore, the reduction in the angular distance per step can make the motion appear smoother at the output.

A fundamental rule in motion control is that the load inertia should ideally be equal to or less than the motor rotor inertia for optimal responsiveness and to prevent instability. In many applications, the load inertia is much greater than the motor inertia. The gearbox reduces the reflected load inertia to the motor by the square of the gear ratio. For instance, a 10:1 gearbox reduces the reflected inertia by a factor of 100 (10²). This inertia matching allows the stepper motor to accelerate and decelerate the load more rapidly and with greater control, minimizing the risk of step loss and oscillation. This results in a more robust and dynamically responsive system.

The unique set of advantages offered by the stepper motor and planetary gearbox duo makes it the preferred solution for a vast array of applications across diverse industries. This combination excels in scenarios demanding high torque, precise positioning, compactness, and reliable performance in demanding environments. From moving heavy loads with precision to ensuring minute adjustments in sensitive equipment, these systems form the mechanical backbone of modern automation and precision machinery. Their versatility and robustness ensure their continued relevance in both established and emerging technological fields.

In the world of robotics, joint actuators require high torque in a compact package to articulate robot arms, and high torque stepper motor with planetary gearbox for robotic arms is the quintessential solution for this demand. The high torque density allows for powerful movements without bulky components, while the low backlash ensures precise and repeatable positioning of the end-effector. This is crucial for tasks such as assembly, pick-and-place, welding, and painting. Automated guided vehicles (AGVs) also utilize these systems for accurate wheel control and steering mechanisms.

The medical field demands utmost reliability, precision, and often, sterilization capabilities. Stepper motor planetary gearboxes are found in a wide range of medical devices, including surgical robots, DNA sequencing instruments, infusion pumps, ventilator valves, and automated sample handling systems. Their ability to provide smooth, precise, and controlled motion is essential for patient safety and the accuracy of diagnostic and therapeutic procedures. The often compact nature of these drives is a significant benefit in space-constrained medical devices.

Industrial machinery for packaging, printing, and textiles operates at high speeds and requires precise synchronization of multiple axes. Planetary gearboxes provide the necessary torque to drive rollers, cutters, and feeders, while the stepper motor ensures perfect registration and timing. For example, in a packaging machine, they control the film feed length with high accuracy, while in a printer, they precisely advance the paper. The durability of planetary gearboxes ensures longevity even in harsh industrial environments with continuous operation.

Applications such as satellite antenna positioning, telescope movement, laser beam steering, and CNC rotary tables require very fine angular resolution and high positional accuracy. The increased resolution provided by the gearbox, combined with the holding torque of the stepper motor, makes this combination ideal for these tasks. The system can make extremely small, controlled movements and then hold its position firmly against external disturbances, which is a key requirement for stepper planetary gearbox for precise positioning applications.

In aerospace, components must be lightweight, reliable, and capable of operating in extreme conditions. Stepper motor and planetary gearbox systems are used in various actuator applications, such as controlling flaps, adjusting sensors, and operating valves. Their ability to provide high torque without relying on complex hydraulic systems is a major advantage. The robustness of the planetary gear design ensures performance under high vibration and wide temperature ranges, making it suitable for low backlash planetary gearbox for stepper motor in aerospace uses.

To truly master the application of these systems, a deeper understanding of their performance characteristics and inherent trade-offs is necessary. This involves looking beyond the datasheet specifications and comprehending how the components behave under dynamic conditions, how they interact with the drive electronics, and what limitations must be considered during the design phase. This technical exploration will cover aspects such as resonance damping, thermal management, and the critical choice between different gearbox performance classes, providing a more holistic view for the experienced designer.

Backlash is an unavoidable mechanical clearance between mating gear teeth that results in a dead zone where input movement does not produce output movement. For positioning systems, especially those that involve bidirectional movement, minimizing backlash is paramount. Planetary gearboxes are available in different backlash classes, often designated as precision, standard, or economic. Precision gearboxes undergo special manufacturing processes, use higher-quality materials, and may incorporate anti-backlash designs to achieve very low values (often below 5 arc-min). The trade-off is a significant increase in cost. The choice of backlash class should be dictated by the accuracy requirements of the application; not every system needs a ultra-precision unit, making a cost-effective planetary gearbox for stepper motors a viable option for many less demanding applications.

The following table illustrates typical backlash values for different classes of planetary gearboxes, helping engineers make an informed selection based on their application's precision needs.

| Gearbox Class | Typical Backlash Range (arc-min) | Suitable Applications |

|---|---|---|

| Precision / High-Performance | < 5 | Robotic surgery, optical positioning, military targeting |

| Standard | 5 - 15 | General automation, packaging, material handling |

| Economic | > 15 | Light-duty applications, door actuators, non-critical positioning |

Stepper motors are prone to experiencing resonance at certain step rates, which can cause noise, vibration, and even missed steps. The addition of a planetary gearbox can alter the resonant frequencies of the system. The inertia reflected through the gearbox can help dampen these resonances, potentially making the system smoother over a wider speed range. However, the gearbox itself can also introduce torsional resonances if its natural frequency is excited by the motor's step pulses. Proper system design, including the use of microstepping drives that provide smoother current waveforms, is essential to mitigate these effects and ensure stable operation across the entire speed range.

Stepper motors can generate significant heat, especially when holding position at high torque levels. This heat can be conducted into the gearbox. While planetary gearboxes are highly efficient, some energy is lost as heat due to friction between the gear teeth and in the bearings. The combined heat generation from both components must be considered. The continuous output torque rating of a gearbox is often limited by its ability to dissipate heat without damaging the lubrication or components. For demanding duty cycles, it is crucial to ensure that the system's thermal limits are not exceeded. This might involve calculating the expected power losses and, in extreme cases, considering external cooling or selecting a larger gearbox size with a higher thermal mass.

The theoretical superiority of a stepper motor and planetary gearbox system can only be realized in practice with correct installation and diligent maintenance. Improper mounting, misalignment, or neglect can lead to premature failure, increased backlash, and degraded performance. Adhering to established mechanical and operational guidelines is crucial for maximizing the lifespan and ensuring the reliability of the drive system. This section outlines the key practical steps and considerations for handling, integrating, and maintaining these precision components.

The foundation of a long-lasting system is precise mechanical assembly. The stepper motor shaft must be perfectly aligned with the gearbox's input shaft to avoid imposing excessive radial or axial loads. Misalignment can cause premature wear on the motor's front bearing and the gearbox's input bearing, leading to failure. Couplings should be used to connect the motor to the gearbox, and these couplings must be chosen to compensate for any minor residual misalignment (e.g., using bellows or beam couplings). The motor and gearbox must be mounted on a rigid, flat surface to prevent housing distortion. All mounting bolts should be tightened evenly and to the specified torque values to ensure a secure and flat fit.

Planetary gearboxes are typically lubricated for life with synthetic grease or oil during manufacturing. This means that under normal operating conditions, they do not require relubrication. However, several factors can change this. Extreme operating temperatures can break down the lubricant over time. Very long operational hours, high loads, or harsh environments may necessitate periodic relubrication or even a change of lubricant type. It is essential to consult the manufacturer's guidelines regarding maintenance intervals and recommended lubricants. Signs that maintenance may be needed include increased operating temperature, a change in noise pitch (whining or grinding), or a noticeable increase in backlash.

Even with proper installation, issues can arise. Common problems include excessive noise, overheating, and premature wear. Noisy operation often points to misalignment, improper mounting, insufficient lubrication, or damaged gear teeth. Overheating can be caused by overloading, excessive duty cycle, high ambient temperature, or incorrect lubrication. A sudden increase in backlash is a clear indicator of internal wear or damage. Systematic troubleshooting involves isolating the component (motor, coupling, gearbox) and checking for each potential cause. Understanding these common failure modes and their symptoms is key to implementing a custom planetary gearbox design for specific stepper motor applications that avoids these pitfalls from the outset.