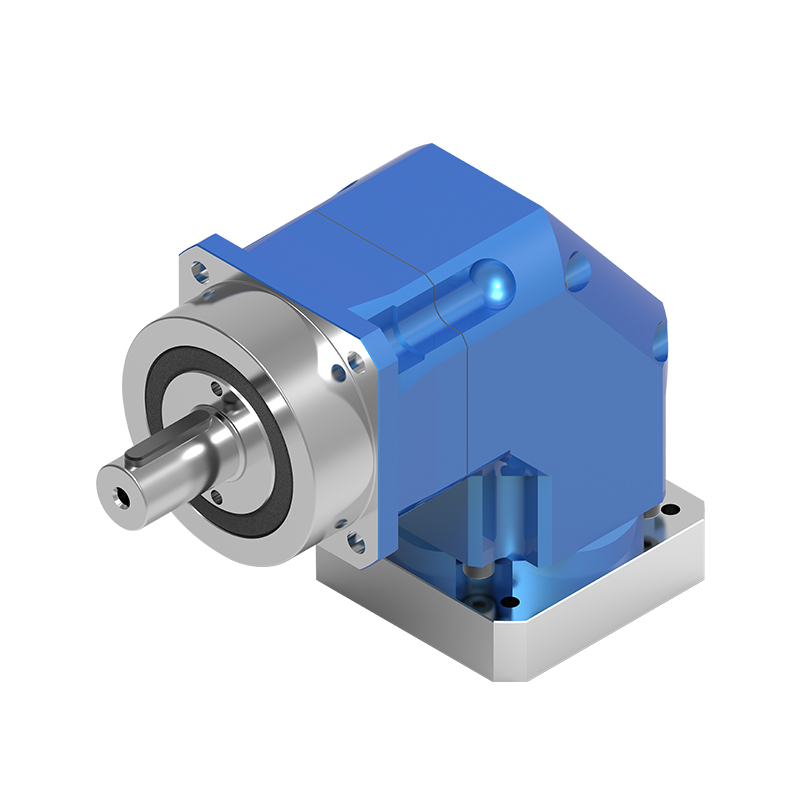

Low Backlash High Precision Torque AHB Planetary Gearbox Reducer

Cat:Planetary Reducer

Features of planetary reducer 1. Quiet: Use helical gears to achieve smooth and quiet operation;2. H...

See DetailsHarmonic reducers, also known as strain wave gearing, are critical components in precision machinery, offering high torque capacity, exceptional positional accuracy, and compact design. Their unique operating principle, utilizing a flexible spline, wave generator, and circular spline, enables superior performance in applications requiring precise motion control. Industries such as robotics, aerospace, medical devices, and advanced manufacturing rely heavily on harmonic reducers for their ability to maintain performance under demanding conditions. The selection of a reliable harmonic reducer is not merely a technical decision but a strategic investment in operational efficiency and long-term productivity. This article explores the essential factors for choosing durable harmonic reducers, focusing on key performance metrics, material considerations, and maintenance practices that ensure extended service life and consistent performance in industrial environments.

Selecting a harmonic reducer that will withstand the test of time requires a thorough evaluation of several engineering and operational parameters. A superficial selection based solely on initial cost or basic specifications can lead to premature failure, unplanned downtime, and increased total cost of ownership. Instead, a holistic approach that considers the specific demands of the application, environmental conditions, and long-term performance expectations is essential for making an informed decision that aligns with both immediate and future operational goals.

The fundamental performance characteristics of a harmonic reducer—torque capacity, operating speed, and positional accuracy—must be meticulously matched to the application's demands. Underestimating these requirements is a common cause of early component failure and system underperformance.

The longevity of a harmonic reducer is intrinsically linked to the materials used in its construction and the quality of its manufacturing processes. The flex spline, in particular, undergoes cyclic deformation and is therefore the component most susceptible to fatigue failure.

Even with a well-selected reducer, understanding and mitigating common performance challenges is key to achieving long-term reliability. Proactive management of these issues prevents unexpected failures and maintains system accuracy.

Heat is a primary adversary of any precision gear system. In harmonic reducers, inefficiencies in the meshing process and bearing friction convert mechanical energy into heat. Excessive operating temperatures can degrade the lubricant, alter material properties, and induce thermal expansion that disrupts precise gear meshing. To address this, engineers should consider the reducer's thermal rating, ensure adequate heat dissipation through mounting surfaces or external cooling, and select a lubricant with a high thermal stability rating. Applications with frequent start-stop cycles or high peak loads are particularly prone to thermal issues and require careful thermal analysis during the design phase. A critical question for many engineers is, how to reduce backlash in a harmonic drive system over time. While harmonic drives are renowned for their low initial backlash, it can gradually increase due to wear, especially if the system is subjected to shock loads or improper lubrication. The most effective strategy is a proactive one: selecting a reducer with a high torsional stiffness and a design that minimizes stress concentration on the flex spline, combined with a rigorous preventive maintenance schedule that includes regular checks for wear and lubrication replenishment.

In high-cycle or high-speed automation, vibration and noise can be indicators of underlying problems or can themselves cause issues with peripheral equipment. While harmonic reducers are generally quieter than many other gear types, they are not immune. Vibration can stem from misalignment with the motor or load, an unbalanced wave generator, or internal component wear. Noise is often a direct consequence of vibration or inadequate lubrication. To ensure smooth operation, it is essential to follow precise mounting procedures, use high-quality couplings, and perform periodic vibration analysis as part of a condition-based maintenance program. This leads directly to the topic of harmonic drive maintenance schedule for robotics. Robotic systems, with their complex programming and demanding duty cycles, require a tailored maintenance approach. A comprehensive schedule should include periodic inspections for unusual noise or vibration, verification of mounting bolt torques, monitoring of operating temperature, and strict adherence to lubrication replacement intervals as specified by the manufacturer, which are often based on both operating time and environmental conditions.

To make a fully informed decision, it is valuable to compare harmonic reducers against other common speed reduction technologies, such as planetary gearboxes and cycloidal drives. Each technology has its own set of advantages and trade-offs, making them suitable for different application scenarios. The choice between them often involves a careful balance of performance priorities, including precision, size, torque density, cost, and maintenance requirements.

The following table provides a high-level comparison of these three technologies across several key parameters. It is important to note that these are general characteristics, and specific models from different manufacturers may vary.

| Parameter | Harmonic Reducer | Planetary Gearbox | Cycloidal Drive |

|---|---|---|---|

| Backlash | Very Low (often near-zero) | Low to Medium | Low to Zero |

| Torque Density | High | High | Very High |

| Positional Accuracy | Excellent | Good | Excellent |

| Torsional Stiffness | High | Very High | Extremely High |

| Efficiency | High (80-90%) | High (90-97%) | Medium-High (75-85%) |

| Compactness | Excellent (thin profile) | Good | Good (requires more axial space) |

| Shock Load Resistance | Moderate | Good | Excellent |

| Cost | Higher | Medium | Higher |

As the table illustrates, harmonic reducers excel in applications where minimal backlash, high positional accuracy, and a compact, lightweight design are paramount. They are the preferred choice in articulated robotics, aerospace actuation, and semiconductor manufacturing equipment. In contrast, planetary gearboxes offer high efficiency and stiffness at a more competitive cost, making them suitable for a wide range of general industrial automation tasks where ultra-high precision is not the primary driver. Cycloidal drives provide exceptional shock load resistance and longevity, often finding their niche in heavy-duty industrial robots and machinery subject to high-impact loads. For those working with high torque density harmonic reducer applications, the choice often narrows down to harmonic and cycloidal technologies. While cycloidal drives can sometimes offer a higher pure torque-to-size ratio, harmonic reducers provide a superior combination of torque density, precision, and smooth motion, which is why they are indispensable in the joints of collaborative and industrial robots where space is constrained but performance cannot be compromised.

The selection of a high-quality harmonic reducer is only the first step toward achieving long-term reliability. A well-defined and consistently executed maintenance strategy is what ultimately determines the component's operational lifespan and protects the investment. A reactive approach, waiting for a failure to occur, results in costly downtime and potential collateral damage to other system components.

A proactive maintenance plan is built on a foundation of routine, time-based tasks. These activities are designed to prevent the common failure modes associated with harmonic reducers and are typically outlined in the manufacturer's documentation.

For critical applications where unplanned downtime is unacceptable, moving from preventive to predictive maintenance is the ultimate goal. This involves using sensor data to monitor the health of the reducer in real-time and to perform maintenance only when it is actually needed.

When considering cost-effective harmonic reducer alternatives for heavy machinery, it is vital to adopt a total-cost-of-ownership perspective. While a planetary gearbox might have a lower initial purchase price, its potentially higher maintenance needs and shorter lifespan in a demanding application could make it more expensive over a 10-year period compared to a robust harmonic or cycloidal reducer that, with proper care, requires less frequent intervention and offers greater operational consistency. Similarly, understanding the lifespan expectancy of a harmonic reducer in CNC machines is not about a fixed number of hours, but rather a function of the applied load, operating speed, and maintenance diligence. In a well-maintained CNC environment with stable loads, a harmonic reducer can reliably operate for tens of thousands of hours, whereas one subjected to frequent shock loads and poor lubrication may fail significantly earlier. The key is to integrate the reducer into a holistic system management plan that prioritizes condition monitoring and proactive care.

The journey to selecting a reliable harmonic reducer for long-term industrial use culminates in a synthesis of technical analysis, operational understanding, and strategic foresight. It requires looking beyond the data sheet to consider how the component will interact with the entire mechanical system and the operating environment over its intended lifespan. By thoroughly evaluating performance requirements, understanding material and construction quality, planning for effective thermal and vibration management, and committing to a rigorous maintenance protocol, engineers and plant managers can ensure that their harmonic reducers deliver not just immediate performance, but also decades of dependable service. This diligent approach transforms the harmonic reducer from a simple component into a cornerstone of industrial productivity and reliability.