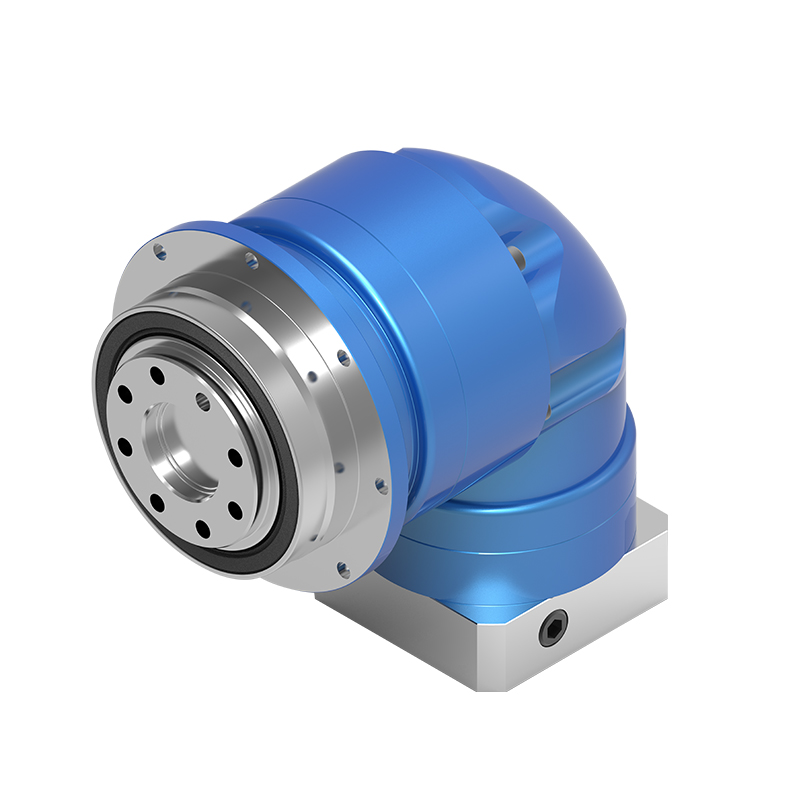

Low Noise Multi specification Integrated-Structure Planetary Reducer AHS Series

Cat:Planetary Reducer

Planetary reducers occupy an important position in the field of industrial automation. The high-prec...

See DetailsHarmonic reducers have become essential components in modern robotics, offering unmatched precision and reliability. Manufacturers in industries ranging from automotive automation to aerospace are increasingly incorporating these devices to enhance robotic performance. By providing high reduction ratios in a compact form factor, harmonic reducers enable smooth and accurate motion control, which is critical for applications where millimeter-level accuracy is required. In addition, the unique strain wave gearing mechanism allows for zero backlash, high torque density, and long service life, making harmonic reducers a preferred choice over conventional gear systems.

The adoption of high-precision harmonic reducer applications is growing rapidly in fields that demand extreme accuracy. Robotics, medical equipment, and aerospace systems benefit significantly from these reducers because they maintain precise positioning even under high loads. Their ability to provide consistent torque and minimal backlash ensures that robotic arms and automated machines operate smoothly and efficiently. Manufacturers value this precision as it directly impacts productivity, product quality, and operational reliability.

| Application | Benefit |

| Industrial Robotics | Improved motion accuracy and repeatability |

| Aerospace | Compact design with high torque density |

| Medical Devices | High reliability and zero backlash for critical procedures |

When comparing harmonic reducers with planetary gears, several key differences make harmonic reducers more favorable in robotics applications. Planetary gears are efficient for standard load applications but often suffer from backlash, size constraints, and limited precision. In contrast, harmonic reducers offer high reduction ratios with zero backlash, compact dimensions, and superior torque transmission. These features allow manufacturers to achieve smoother motion control, higher precision, and better overall performance in robotic systems.

| Feature | Harmonic Reducer | Planetary Gear |

| Backlash | Near zero | Moderate |

| Precision | High | Medium |

| Size | Compact | Larger |

| Torque Density | High | Medium |

Understanding harmonic reducer common faults and solutions is crucial for maintaining robotic systems. Despite their reliability, harmonic reducers may experience wear over long-term use, lubrication issues, or misalignment. Manufacturers benefit from implementing preventive maintenance strategies, such as regular inspections, proper lubrication, and monitoring operational loads. By addressing these factors, the longevity and performance of harmonic reducers can be optimized, reducing downtime and maintenance costs.

| Fault | Cause | Solution |

| Excessive wear | Improper lubrication | Regular maintenance schedule |

| Vibration | Misalignment | Re-align components carefully |

| Reduced accuracy | Overload | Ensure load within specifications |

Selecting reliable suppliers for harmonic reducers is a key factor for manufacturers. A trustworthy supplier ensures consistent quality, timely delivery, and technical support. When evaluating suppliers, manufacturers should consider factors such as production capability, quality certifications, customer support, and product range. By choosing reputable suppliers, companies can maintain high operational efficiency and avoid downtime caused by substandard components.

| Factor | Consideration |

| Quality | ISO certifications, precision inspection reports |

| Technical Support | On-site assistance and troubleshooting guidance |

| Delivery Time | Short lead times for urgent applications |

The harmonic reducer selection guide helps manufacturers choose the appropriate model for robotics applications. Key factors include load capacity, speed ratio, torque requirements, and precision demands. Understanding the operational environment and robot configuration ensures optimal performance. Selecting the right harmonic reducer prevents premature wear, enhances motion control, and ensures reliable long-term operation. This guide is particularly useful for engineers seeking to integrate high-precision reducers into complex robotic systems.

| Parameter | Recommendation |

| Load Capacity | Calculate based on maximum payload |

| Speed Ratio | Choose ratio ensuring smooth motion |

| Torque | Ensure safety margin above operational requirement |

The primary advantage is their ability to deliver high-precision motion with zero backlash, compact size, and high torque density. This allows robots to perform accurate, smooth, and repeatable tasks even under heavy loads. Compared to conventional gears, harmonic reducers improve reliability and reduce maintenance requirements.

High-precision harmonic reducers enhance robotic accuracy, repeatability, and speed control. This is critical for pick-and-place operations, assembly lines, and automated inspection systems. Their zero-backlash design ensures minimal positional error and consistent performance in complex manufacturing environments.

Common issues include excessive wear, vibration, and reduced accuracy, often caused by poor lubrication, misalignment, or overload. Solutions involve proper lubrication schedules, correct installation alignment, and ensuring operational loads remain within specifications. Regular monitoring and preventive maintenance significantly extend the reducer’s lifespan.

Manufacturers should consider load capacity, torque requirements, speed ratio, and precision needs. Evaluating the operating environment and intended robotic tasks ensures the right reducer choice. Consulting supplier technical documentation and performing application-specific calculations are recommended practices.

Harmonic reducers offer zero backlash, higher precision, and a compact design, making them ideal for space-constrained robotic applications. They provide superior torque density and smoother motion control compared to planetary gears, which often exhibit moderate backlash and lower precision.