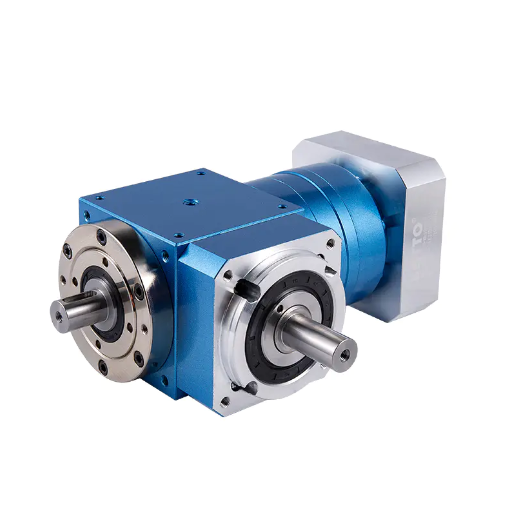

Low Backlash High Precision Torque AHB Planetary Gearbox Reducer

Cat:Planetary Reducer

Features of planetary reducer 1. Quiet: Use helical gears to achieve smooth and quiet operation;2. H...

See DetailsIn the world of precision motion control and power transmission, the planetary gearbox stands as a cornerstone of engineering excellence. Known for its compact size, high efficiency, and exceptional load distribution, this gearbox design is indispensable across countless industries. However, when the requirement shifts towards applications demanding immense rotational force within a constrained space, the high torque planetary gearbox becomes the undisputed champion. This comprehensive guide delves into the intricacies of these robust powerhouses, exploring their design principles, critical applications, and key selection criteria. We will navigate through specific niches, addressing common queries such as what is the maximum torque for a planetary gearbox, high torque planetary gearbox for robotics, high torque density planetary gearbox design, how to calculate torque in a planetary gear system, and the nuances of planetary gearbox vs cycloidal for high torque. By understanding these elements, engineers and decision-makers can specify the optimal gearbox solution for their most demanding challenges.

Before dissecting the high-torque variants, it is essential to grasp the fundamental mechanics that make planetary gearboxes uniquely suited for such demanding roles. A planetary gear set, also known as an epicyclic gear set, consists of three primary components: a central sun gear, multiple planet gears that rotate around the sun gear, and a ring gear (or annulus) that encases the entire system. The planet gears are held together and spaced by a carrier. This ingenious configuration allows for torque transmission and speed reduction through multiple parallel paths.

The synergy between the components is what grants the planetary gearbox its remarkable characteristics. Each part plays a pivotal role in the system's overall performance and ability to handle high loads.

The principle of load sharing is paramount. Unlike a simple parallel-shaft gear pair where one tooth bears the full load, a planetary system splits the transmitted torque among several planet gears. This distribution significantly reduces stress on individual gear teeth, minimizes wear, and allows for a more compact design to handle the same power compared to other architectures. This inherent characteristic directly answers the query about high torque density planetary gearbox design. Torque density refers to the amount of torque transmitted per unit volume or weight. The planetary design, with its multiple load paths and concentric layout, inherently offers one of the highest torque densities available in gear technology, making it ideal for space- and weight-constrained applications like aerospace, robotics, and mobile machinery.

The unique capabilities of high torque planetary gearboxes make them the preferred choice in fields where power, precision, and compactness cannot be compromised. These applications often involve starting under heavy load, operating at slow speeds with immense force, or requiring precise motion control under fluctuating resistance.

In modern robotics, from heavy-duty industrial arms to agile mobile robots, joint actuators require a combination of high torque, low backlash, and compact size. A high torque planetary gearbox for robotics is critical in the rotary joints of robotic arms, where it must lift, position, and manipulate significant payloads with high repeatability. The compact design allows for sleeker arm profiles, while the high torque density ensures powerful movements without excessive weight at the joint, improving overall system dynamics and energy efficiency. Furthermore, the rigidity and torsional stiffness of precision planetary gearboxes are essential for maintaining accuracy during high-force operations, such as in assembly, welding, or machining applications performed by robots.

Industries such as mining, construction, and material handling rely on equipment that can generate enormous forces. High torque planetary gearboxes are found in:

In these environments, durability and reliability are as important as torque capacity. The gearboxes must withstand shock loads, continuous operation, and often harsh environmental conditions.

Wind turbine pitch and yaw drives are quintessential high-torque, low-speed applications. Planetary gearboxes are used to adjust the angle of the blades (pitch control) to optimize power capture and to rotate the nacelle (yaw control) to face the wind. These systems must operate reliably for decades with minimal maintenance, often in remote and exposed locations. The high torque output is necessary to move massive blade assemblies against strong wind forces, and the compact, integrated design of planetary systems is ideal for the nacelle's confined space.

Selecting the right high torque planetary gearbox is a nuanced process that extends beyond simply matching a torque number. Several interrelated specifications must be considered to ensure optimal performance, longevity, and integration with the overall system.

A fundamental question engineers face is what is the maximum torque for a planetary gearbox. It is crucial to distinguish between different torque ratings provided by manufacturers, as exceeding these limits can lead to catastrophic failure.

Therefore, when specifying a gearbox, one must analyze the application's torque profile—identifying both the continuous operational torque and any anticipated peak events—to select a unit whose rated and peak torque ratings safely exceed these values with an appropriate safety factor.

Proper integration requires accurate calculations. A core competency is understanding how to calculate torque in a planetary gear system. The fundamental relationship involves the gear ratio and efficiency.

The output torque (T_out) of a planetary gearbox can be derived from the input torque (T_in), the gear ratio (i), and the mechanical efficiency (η). The formula is generally expressed as: T_out ≈ T_in * i * η. It is important to note that in a reduction gearbox (where output speed is lower than input speed), the output torque is multiplied. The gear ratio 'i' is defined as the input speed divided by the output speed. For a simple planetary stage with a fixed ring gear, input on the sun, and output on the carrier, the ratio is 1 + (Number of teeth on Ring Gear / Number of teeth on Sun Gear). However, calculating the exact torque also requires considering the service factor, which accounts for dynamic loads, operating hours, and ambient conditions. Furthermore, the input torque from the motor must be known, which is calculated based on the motor's power (P in kW) and speed (n in rpm): T_in = (9549 * P) / n. These calculations form the bedrock of a reliable drive system design.

While planetary gearboxes are excellent for many high-torque scenarios, they are not the only option. A common and important comparison is planetary gearbox vs cycloidal for high torque. Each technology has distinct advantages and trade-offs, making them suitable for different application profiles.

The cycloidal drive, based on the principles of cycloidal motion, uses disc-shaped elements with lobes that mesh with pins on a stationary ring. This design offers exceptional shock load resistance, very high reduction ratios in a single stage, and often lower backlash. However, it can have slightly lower efficiency, especially at lower ratios, and may produce more vibration at high speeds due to its kinematic motion. The planetary gearbox, in contrast, typically offers higher efficiency across a broad range of ratios, smoother operation at higher input speeds, and excellent torque density. Its main limitations for extremely high shock loads might be the reliance on precise gear meshing, though modern designs are highly robust. The choice often comes down to the specific priorities of the application: ultra-high shock load capacity and single-stage ultra-high ratio favor cycloidal, while high efficiency, smooth operation, and excellent torque density favor planetary.

| Feature | High Torque Planetary Gearbox | Cycloidal Drive (for High Torque) |

|---|---|---|

| Torque Density | Very High | High |

| Single-Stage Reduction Ratio | Typically 3:1 to 10:1 (higher with multiple stages) | Can be very high (e.g., 30:1 to 100:1+) in a single stage |

| Efficiency | Very High (often >95% per stage) | High, but can be slightly lower, especially at very high ratios |

| Backlash | Can be made very low with precision manufacturing | Typically very low to zero-backlash |

| Shock Load Resistance | High | Exceptional |

| Operational Smoothness | Very smooth, especially at higher speeds | Smooth at output, but input can experience vibration due to disc motion |

| Typical Applications | Robotics, AGVs, precision industrial automation, packaging, winches. | Heavy-duty robotics, crane slewing, mining equipment, applications with extreme shock loads. |

The theoretical advantages of a planetary gearbox can only be realized through meticulous manufacturing and advanced engineering. The performance, particularly in high-torque, high-precision applications, is directly tied to the quality of materials, the accuracy of gear tooth profiles, and the integrity of the assembly process.

For a company like BEITTO, specializing in high precision planetary reducers, the commitment to precision is paramount. Adherence to advanced R&D technologies and meticulous production processes, such as those honed in leading global manufacturing centers, is not merely a quality statement but a technical necessity. High torque transmission demands perfect load sharing among the planet gears. Any geometric inaccuracy in gear teeth, misalignment of bearings, or imperfection in the carrier's bore spacing will cause one planet gear to carry a disproportionate share of the load. This leads to premature wear, increased noise, reduced efficiency, and ultimately, a lower actual torque capacity and shorter service life than the design intended. Precision manufacturing ensures that the load is distributed as per the theoretical design, maximizing the gearbox's potential and reliability. This involves state-of-the-art gear hobbing and grinding machines, coordinate measuring machines (CMM) for verification, and controlled assembly environments.

The components of a high torque planetary gearbox are subjected to immense cyclic stresses. The selection of alloy steels for gears and shafts, coupled with precise heat treatment processes like case carburizing and hardening, is critical. This creates a hard, wear-resistant surface on the gear teeth to handle the contact stresses, while maintaining a tough, ductile core to absorb shock loads and prevent brittle fracture. The quality of bearings, which support the planetary carrier and shafts, is equally vital. They must have high dynamic load ratings and be precisely preloaded to minimize deflection under load, contributing directly to the system's torsional stiffness and positional accuracy. Advanced surface treatments and lubricants are also employed to minimize friction and wear, further enhancing efficiency and longevity, especially in the context of achieving superior high torque density planetary gearbox design where every component must perform optimally.

Beyond the standard catalog product, the most demanding applications often require customized solutions. A deep engineering partnership allows for gearboxes to be tailored to specific needs. This could involve modifying the gear ratio, altering the input/output shaft configuration, using special seals for harsh environments (IP67/IP69K), incorporating integrated sensors for condition monitoring, or designing a complete mechatronic system with a matched servo motor. The location of BEITTO within a dedicated national electromechanical components industrial park provides an ecosystem conducive to such advanced engineering and integration, facilitating collaboration and access to specialized supply chains. This holistic approach from design to finished product ensures that the high torque planetary gearbox is not just a component, but a perfectly integrated driver of performance in the end-user's machine.

Specifying the correct high torque planetary gearbox is a strategic decision that impacts machine performance, reliability, and total cost of ownership. It requires a systematic approach that balances technical requirements with practical constraints.

By following this methodology, engineers can move from a vague need for a "high torque planetary gearbox for robotics" or industrial machinery to a precise technical specification that ensures a successful and durable implementation.

The landscape for high torque transmission is continuously evolving. Trends include the increasing integration of smart features like embedded sensors for predictive maintenance, the development of even more compact and lightweight designs using advanced composites and manufacturing techniques like additive manufacturing for certain components, and the push for higher efficiency to meet global energy standards. Furthermore, the demand for ultra-low backlash and high stiffness in collaborative robotics and advanced automation will continue to drive innovation in precision gear manufacturing and assembly techniques. Understanding these trends allows designers to future-proof their equipment and leverage the latest advancements in planetary gearbox technology to gain a competitive edge.

In conclusion, the high torque planetary gearbox is a sophisticated and versatile engineering solution that bridges the gap between powerful motion and precise control. From understanding its fundamental mechanics and calculating its capabilities to comparing it with alternatives and appreciating the critical role of precision manufacturing, a comprehensive knowledge base is essential. By addressing key questions around maximum torque, robotic applications, torque density, calculations, and technology comparisons, this guide provides a foundation for making informed decisions that will ensure the success of any high-performance drive system.