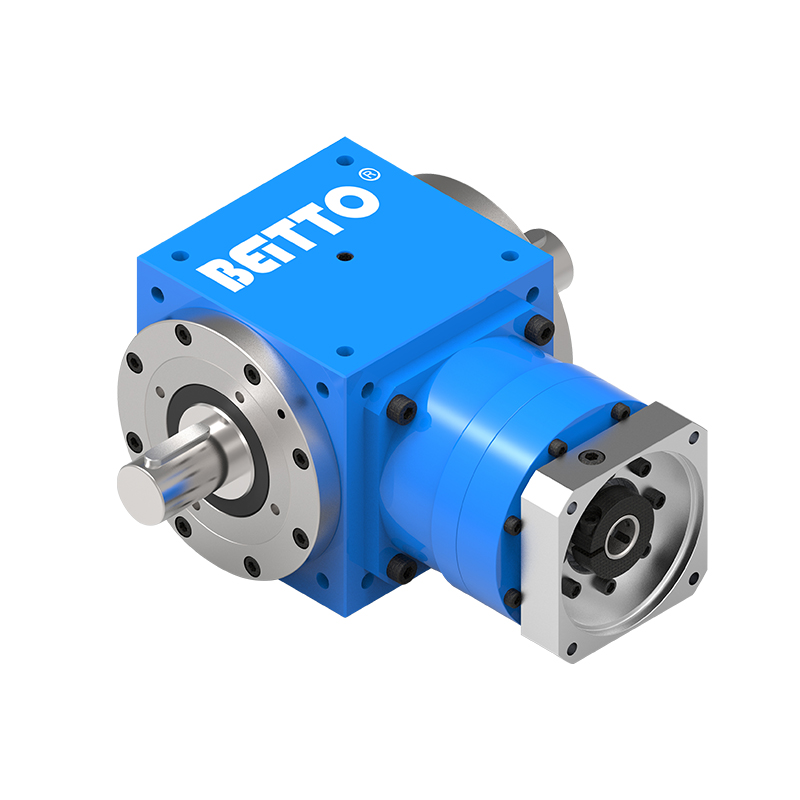

Low Backlash High Precision Torque AHB Planetary Gearbox Reducer

Cat:Planetary Reducer

Features of planetary reducer 1. Quiet: Use helical gears to achieve smooth and quiet operation;2. H...

See DetailsA Right-angled Gearbox Reducer plays a critical role in equipment where directional power transmission and limited installation space coexist. Its design allows torque to be transferred at a 90 degree angle, enabling engineers to achieve complex layouts without increasing system footprint. This structure contributes to higher flexibility in assembly, reduced shaft alignment issues, and improved durability of connected components. As compact machinery grows in demand, the need for right-angled gearbox reducer for compact machinery continues to increase. In addition, the internal configuration optimizes rotational force, ensuring more efficient operation even under high-load conditions. This efficiency is especially beneficial in automated equipment, conveyor systems, packaging lines, and precision industrial devices that require continuous, stable output for long periods.

| Feature | Benefit |

| 90 degree torque transfer | Improved layout flexibility |

| Compact housing | Ideal for space-limited equipment |

| Reinforced gear structure | Increased endurance for continuous operation |

Straight gearboxes and right-angle types differ significantly in structural design and intended applications. While straight gearboxes transmit motion along a linear axis, a Right-angled Gearbox Reducer shifts output direction by 90 degrees through bevel gears or worm mechanisms. This distinction gives industries more options depending on the complexity and spatial orientation of their setups. When comparing both configurations, engineers often consider operating noise, torque levels, transmission smoothness, and energy usage. As automation and compact machinery evolve, the demand for systems like the industrial right angle gearbox for automation systems has risen, as these models excel in integrated mechanical frameworks where precision motion paths are crucial.

| Type | Motion Path | Typical Use |

| Straight Gearbox | Linear | Standard machinery |

| Right-angle Gearbox | 90-degree | Compact or irregular layouts |

Modern right-angle designs are engineered to support equipment that requires high power within tight mechanical envelopes. By integrating optimized gear materials, surface treatments, and improved lubrication paths, today's high-torque right-angle speed reducer models deliver reliable performance and extended operational life. Their ability to maintain torque output consistency even under fluctuating loads makes them ideal for conveyor drives, robotic systems, and light industrial tools. Additionally, the compact nature ensures manufacturers can design smaller machinery without sacrificing performance. Such innovations further enhance the competitiveness of systems that rely on a Right-angled Gearbox Reducer to achieve seamless directional force control.

| Parameter | Impact |

| Torque capability | Improves heavy-load performance |

| Gear efficiency | Enhances energy transfer |

| Compact structure | Reduces overall machine footprint |

Noise control has become an essential design factor in modern industrial machinery. A low-noise right-angle reduction gearbox maintains performance levels without compromising on comfort or safety. Manufacturers have incorporated smoother gear meshing technology, improved bearing alignment, and optimized tooth geometry to minimize vibration and unwanted sound. These enhancements help maintain precision across repetitive operating cycles and reduce fatigue on connected components. In applications such as medical automation, precision robotics, and laboratory machinery, quiet operation is not simply a preference but a requirement. When integrated correctly, a Right-angled Gearbox Reducer provides both acoustic control and mechanical reliability.

| Noise Level | Application Type |

| Low | Precision instruments |

| Medium | General automation |

| High | Heavy-duty machinery |

Selecting the appropriate reducer requires understanding how torque, speed reduction ratios, and gear composition influence overall performance. A Right-angled Gearbox Reducer must match the intended machine’s operational load and runtime frequency. When selecting a model for compact equipment, evaluating torque-to-size ratio is crucial. Engineers working with right-angled gearbox reducer for compact machinery often prioritize models with reinforced bevel gears or worm structures, depending on the application’s torque requirements. Additionally, heat dissipation capability, lubrication channels, and shaft configuration determine the long-term reliability of the unit.

| Evaluation Factor | Importance |

| Torque rating | Affects load capacity |

| Speed ratio | Controls output speed |

| Gear type | Influences efficiency and durability |

Energy efficiency is becoming a central consideration for industrial equipment designers. A energy-efficient right-angle drive reducer integrates precision machining and optimized tooth geometry to reduce frictional losses and improve thermal stability. By minimizing heat buildup, these models maintain consistent performance while lowering energy consumption. For automation systems, efficiency not only cuts operational cost but also contributes to sustainable production goals. When compared to older-generation reducers, modern Right-angled Gearbox Reducer units achieve significantly higher conversion efficiency due to refined materials, tighter tolerances, and smoother meshing surfaces.

| Reducer Type | Efficiency Level |

| Traditional bevel reducer | Medium |

| Modern bevel reducer | High |

| Worm-type reducer | Lower but smoother operation |

Automation systems often depend on controlled, stable, and flexible transmission mechanisms to maintain productivity. An industrial right angle gearbox for automation systems provides consistent torque distribution across conveyor drives, robotic joints, indexing tables, and precision actuators. Its ability to operate reliably in restricted mechanical layouts makes it indispensable in automated assembly and material handling processes. A robust Right-angled Gearbox Reducer also helps reduce system downtime by maintaining stable output even during fast-paced operational cycles.

| Application | Benefit |

| Robotics | Precision and smooth motion control |

| Conveyor lines | Consistent torque delivery |

| Packaging systems | High reliability in continuous cycles |

Right-angle reducers can also be integrated into heavy-duty industrial machines, where high torque, endurance, and resilience are essential. Models such as the high-torque right-angle speed reducer help machinery handle demanding tasks, especially in manufacturing, engineering, and material processing systems. Their reinforced internal structures and heat-resistant housings ensure longevity even under harsh conditions. On the opposite end of the spectrum, precision engineering tools also benefit from the smooth and accurate transmission performance provided by a Right-angled Gearbox Reducer.

| Machine Type | Reducer Strength |

| Construction machinery | High endurance |

| Manufacturing tools | Consistent torque |

| Precision devices | Low vibration operation |

When selecting a Right-angled Gearbox Reducer, you must evaluate torque capacity, reduction ratio, mounting compatibility, lubrication requirements, and expected operational cycles. Consider whether you need a right-angled gearbox reducer for compact machinery or a model designed for heavy loads. Assess materials, thermal behavior, and noise levels based on your application.

Yes. Models such as the industrial right angle gearbox for automation systems are specifically engineered for robotic arms, conveyors, pick-and-place devices, and synchronized motion structures. Their compact structure and directional torque transfer provide excellent flexibility for modern automation layouts.

Choosing a low-noise right-angle reduction gearbox ensures smoother gear meshing, improved tooth design, and optimized lubrication. These reducers minimize vibration and mechanical impact, making them suitable for laboratory equipment, medical machinery, and precision automation.

Yes. A energy-efficient right-angle drive reducer significantly reduces frictional losses compared to traditional models. Bevel gear systems generally offer higher efficiency, while worm reducers provide smoother operation but slightly lower energy conversion rates.