The stepper motor planetary gearbox is a critical component in modern automation and precision machinery. It combines the precise control of a stepper motor with the torque multiplication and compact design of a planetary gearbox, allowing machines to achieve high performance in limited spaces. The integration of related technologies such as precision reduction systems, high torque drive systems, low noise gear transmission, high efficiency power transmission, and compact transmission units further enhances the operational efficiency and reliability of the equipment.

Understanding Stepper Motor Planetary Gearboxes

What is a Stepper Motor Planetary Gearbox?

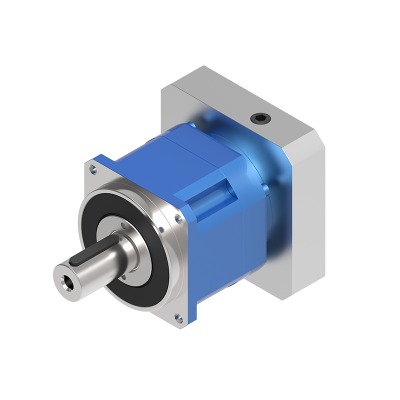

A stepper motor planetary gearbox consists of a stepper motor connected to a planetary gear system enclosed within a rigid housing. The planetary gearbox distributes torque through multiple planet gears rotating around a central sun gear, resulting in high torque output and precision. It is widely used in robotics, CNC machines, medical devices, and industrial automation.

Advantages of Stepper Motor Planetary Gearboxes

- High precision and repeatability for accurate positioning.

- Compact design suitable for limited-space applications compact transmission units.

- High torque output for heavy-load machinery high torque drive systems.

Key Features to Consider

Precision Reduction Systems

Precision reduction systems improve motion control by minimizing backlash and ensuring smooth torque transfer. Typical parameters for precision reduction include:

- Reduction ratio: 3:1 to 100:1

- Backlash: less than 1 arcminute

- Efficiency: 85% to 95%

Low Noise Gear Transmission

Low noise gear transmission is crucial for applications where quiet operation is necessary, such as medical equipment or laboratory instruments. Sound levels can range from 45 to 60 dB depending on the gearbox design and reduction ratio.

Efficient Power Transmission

High efficiency in power transmission high efficiency power transmission ensures minimal energy loss and improved performance. Typical gearbox efficiencies include:

- Single-stage: 90% - 95%

- Two-stage: 85% - 90%

- Three-stage: 80% - 85%

Compact Transmission Units

Compact transmission units are designed for space-limited installations, including small robotic arms, drones, and precision instruments. Their compact size allows for seamless integration into complex mechanical systems without compromising performance.

High Torque Drive Systems

High torque drive systems are essential for applications requiring heavy-load operation. Torque output is influenced by the motor's torque rating and the gearbox reduction ratio:

- Low reduction (3:1 to 5:1): moderate torque increase

- Medium reduction (10:1 to 20:1): significant torque increase

- High reduction (50:1 to 100:1): maximum torque output

Applications of Stepper Motor Planetary Gearboxes

Stepper motor planetary gearboxes are widely used in various fields, including:

- Robotics and automation

- Medical equipment

- Precision instruments and CNC machines

- Industrial machinery with high torque requirements

How to Choose the Right Stepper Motor Planetary Gearbox

When selecting a stepper motor planetary gearbox, consider the following factors:

- Required torque and speed

- Precision and backlash tolerance

- Noise level constraints

- Space limitations and integration needs

- Efficiency and power consumption

Maintenance Tips

Proper maintenance of stepper motor planetary gearboxes ensures longevity and stable performance:

- Regular lubrication and inspection of gears

- Monitoring for wear and tear

- Troubleshooting abnormal noise or vibration

- Replacing worn components promptly

Conclusion

In summary, the stepper motor planetary gearbox plays a vital role in modern machinery, offering high precision, compact design, high torque, and efficient power transmission. Integrating features such as precision reduction systems, low noise gear transmission, and compact transmission units enhances performance in a wide range of applications.

FAQ

- What is a stepper motor planetary gearbox?

A stepper motor planetary gearbox combines a stepper motor with a planetary gear system to provide high torque, precision, and compact size for various automation and precision machinery applications.

- How does a high torque drive system improve performance?

High torque drive systems enhance machinery performance by increasing torque output while maintaining precision and efficiency. This allows heavy-load applications to operate smoothly without sacrificing accuracy.

- Which industries benefit most from compact transmission units?

Industries such as robotics, medical equipment, CNC machining, and precision instruments benefit from compact transmission units. The company has always adhered to the Japanese electromechanical cutting-edge R & D technology, adhering to the Japanese meticulous production process, using leading design and development technology to research new products to achieve optimization and upgrading of the product structure renewal. Pinghu City of Zhejiang Province, located in National Economic and Technological Development Zone, is the province‘s only city approved by the provincial government of the Japanese investment zone, the National (Jiaxing) Electromechanical Components Industrial Park and the National Torch Plan Pinghu Optical and Mechanical Industrial Base core area. Pinghu City, in the northeastern part of Zhejiang Province, is located in China's most dynamic economy of the Yangtze River delta region, neighboring Shanghai to the east and Hangzhou Bay to the south. The city has a land area of 537 square kilometers, a sea area of 1,086 square kilometers and a coastline of 27 kilometers. It has a total population of 800,000 people.